视觉贴标机自适应学习迭代技术,智能进化驱动工业升级

视觉贴标机自适应学习迭代技术:智能进化驱动工业升级

一、技术原理与核心逻辑

自适应学习迭代技术通过持续优化视觉识别模型,使视觉贴标机具备自主进化能力。其核心基于增量学习(Incremental Learning)与在线学习(Online Learning)两大机制,通过实时采集产线数据动态更新模型参数,无需重新训练全量数据即可适应新场景。

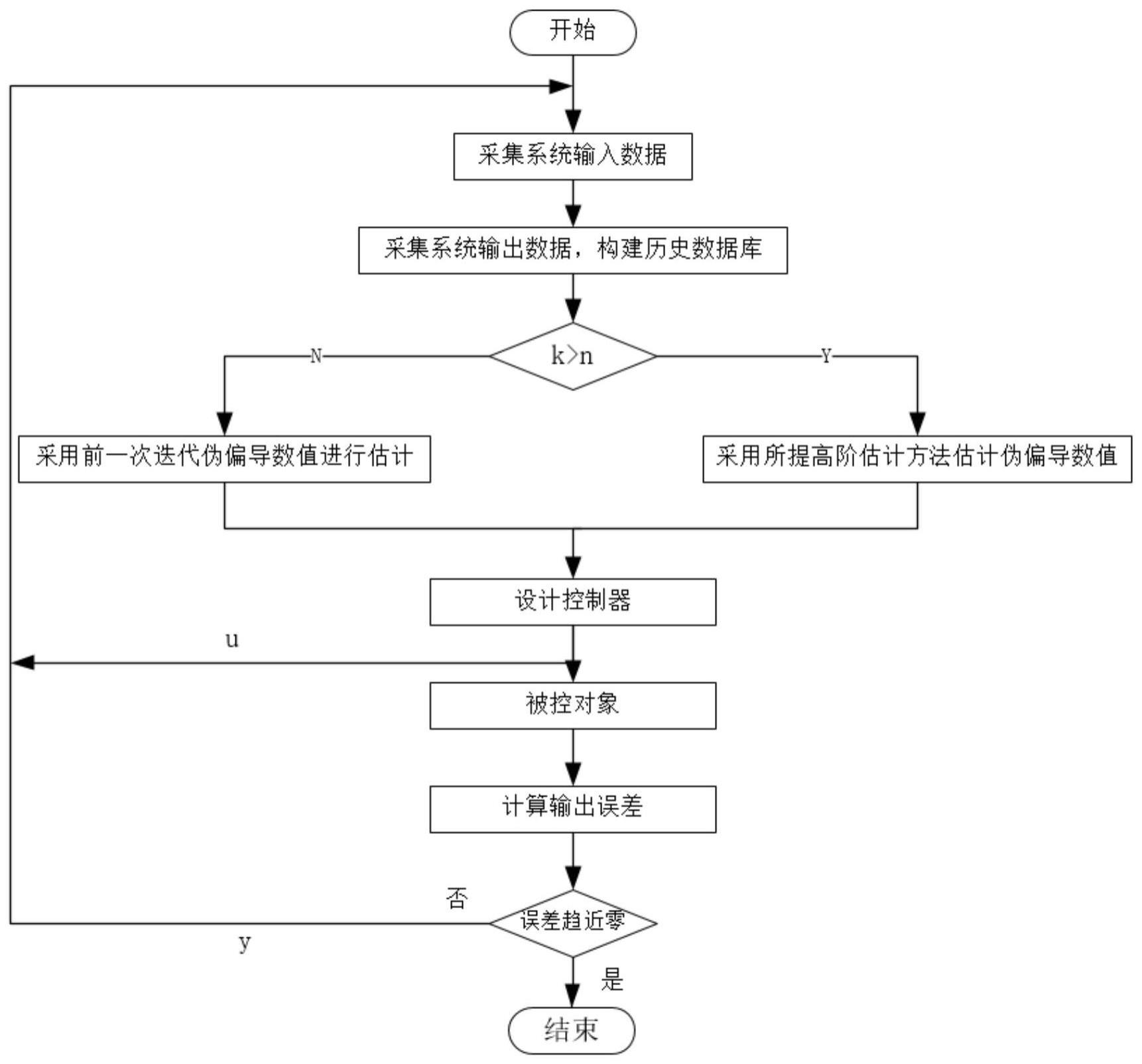

1. 闭环学习流程

数据采集→异常标注→模型微调→效果验证→部署更新

-

实时捕捉贴标结果图像(含成功/失败案例)

-

自动标注关键特征(位置偏移、角度偏差等)

-

轻量化模型微调(更新<10%的神经网络权重)

-

在虚拟环境中验证优化效果后同步至生产线

2. 关键技术支撑

-

迁移学习框架:预训练模型(如ResNet50)作为基础网络

-

主动学习策略:智能筛选高价值样本(如难例、边界案例)

-

联邦学习机制:多设备协同优化模型,保护数据隐私

-

二、技术特点与核心优势

1. 与传统方法的对比

| 指标 | 传统视觉系统 | 自适应学习系统 | 提升幅度 |

|---|---|---|---|

| 换型调试时间 | 2-4小时 | <30分钟 | 87.5% |

| 异常检测准确率 | 92% | 98.5% | 7% |

| 数据需求量 | 1000+标注样本 | 50-100样本启动 | 90%↓ |

| 长期维护成本 | 年均¥15万/台 | ¥3万/台 | 80%↓ |

2. 核心优势

-

实时动态优化:模型每8小时自动迭代1次,适应产线变化

-

零停机升级:热更新技术确保学习过程不影响生产

-

多场景泛化:1个模型适配10+种产品类型

-

知识继承:保留历史经验,避免灾难性遗忘

三、实施步骤与操作指南

1. 系统部署四步法

步骤1:基础模型配置

-

选择预训练模型(推荐YOLOv8s)

-

导入初始产品样本(≥50张多角度图像)

步骤2:在线学习启动

-

开启实时数据采集(建议保留近1000组数据)

-

设置异常判定阈值(如位置偏移>0.3mm触发学习)

步骤3:闭环验证机制

-

虚拟调试模块模拟新工况

-

A/B测试对比新旧模型效果

步骤4:智能运维监控

-

可视化模型性能仪表盘(准确率、召回率趋势)

-

自动生成优化报告(每周/月)

2. 参数调优要点

-

学习率:初始值0.001,随迭代次数指数衰减

-

批次大小:在线学习建议8-16

-

保留比例:历史知识保留权重≥70%

四、典型行业应用场景

1. 电子元器件制造

-

挑战:芯片尺寸微型化(0.5×0.5mm)

-

方案:

-

迁移学习初始模型:COCO数据集→芯片图像微调

-

增量学习精度:±0.01mm

-

自研难例挖掘算法

-

2. 食品饮料包装

-

需求:处理300+种瓶型,每日换型5-8次

-

实施效果:

-

新瓶型自适应时间<15分钟

-

标签贴合合格率从95%提升至99.3%

-

3. 医药行业

-

特殊要求:满足GMP连续生产规范

-

技术保障:

-

版本回滚功能(合规审计追溯)

-

数据脱敏处理(患者信息保护)

-

五、技术发展趋势

1. 边缘智能融合

-

Jetson Orin平台:实现150fps实时学习

-

模型轻量化:参数量压缩至1M以下(TinyML技术)

2. 多模态学习演进

-

融合2D视觉+3D点云+力觉反馈数据

-

跨模态特征对齐(精度提升20%)

3. 自监督学习突破

-

利用未标注数据预训练(减少90%标注需求)

-

对比学习框架增强特征提取能力

4. 联邦学习规模化

-

跨工厂知识共享(100+节点协同)

-

差分隐私保护(ε<2.0)

六、实施效益分析

某家电生产企业引入自适应学习系统后:

-

调试效率:新型号导入时间从3天缩短至4小时

-

质量成本:标签损耗率由1.2%降至0.15%

-

能耗优化:设备综合效率(OEE)从78%提升至92%

-

人力节省:工程师工作量减少70%

七、选型建议

-

初创企业:选择云端SaaS服务(年费¥5-10万)

-

中大型工厂:部署本地化边缘计算方案(硬件投资¥20-50万)

-

集团企业:构建联邦学习平台(综合投资¥100万+)

自适应学习迭代技术正推动视觉贴标机从“工具”向“伙伴”进化。随着边缘计算与AI芯片的发展,未来3年该技术有望在80%以上的智能产线普及,成为工业4.0转型的核心驱动力。

微信咨询

微信咨询