关于我们

标签剥离剥标供料器的工作原理和特点

Time:2025-07-09

Page views: 1555次

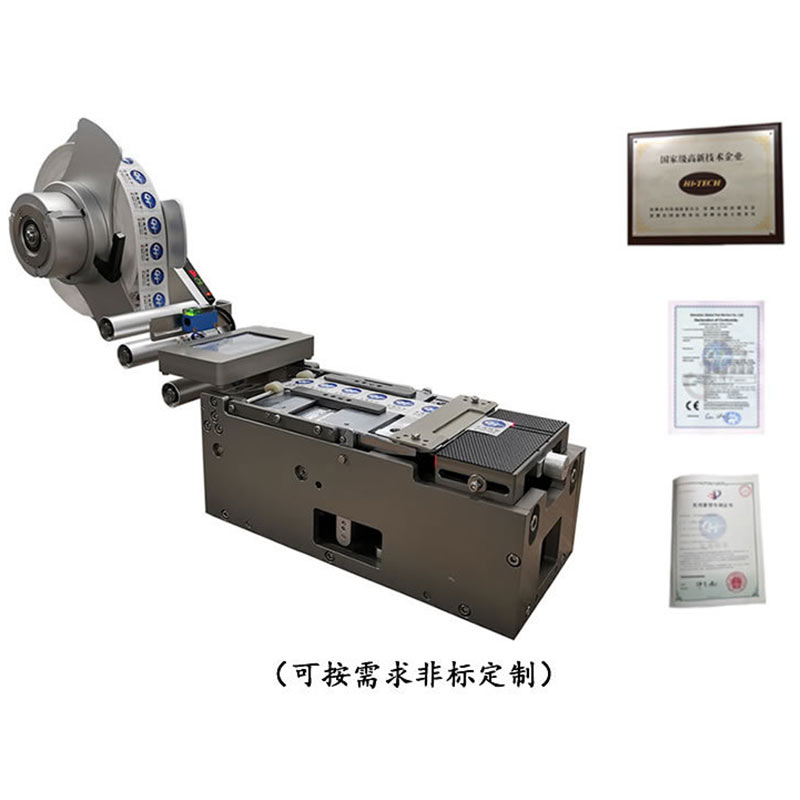

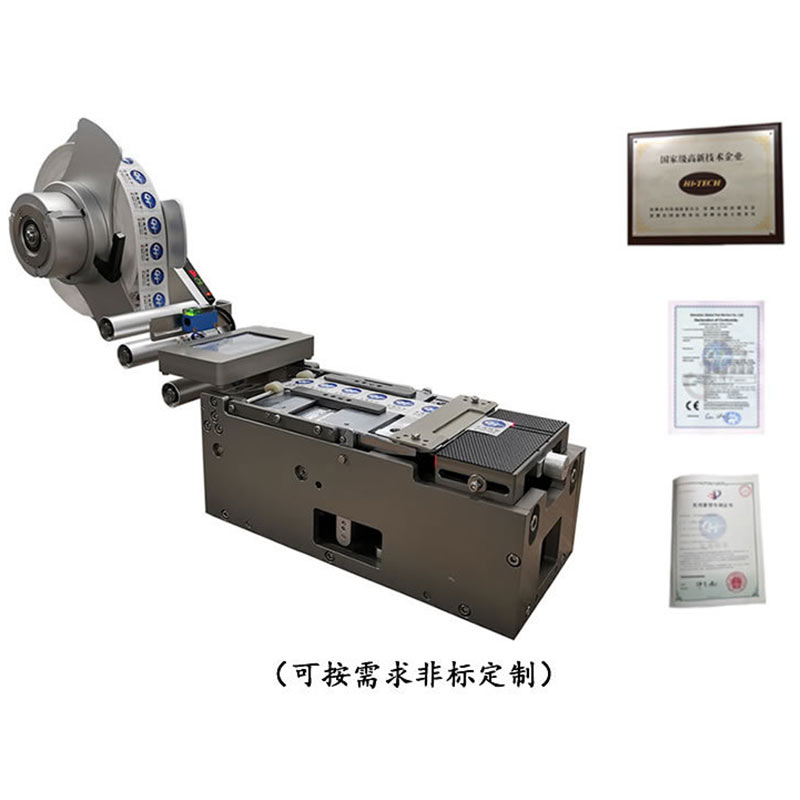

标签剥离机,也叫剥标供料器。在现代自动化生产流程中,剥标机供料器作为实现高效精准贴标的关键设备,凭借独特的工作原理与显著优势,广泛应用于食品、医药、电子等多个行业。了解其工作原理和特点,有助于企业更好地选择和应用这一技术,提升生产效率与贴标质量。

工作原理

标签剥离剥标机供料器的工作主要依赖真空吸附、传感器检测和机械传动等系统协同运作。

首先,成卷的标签在放卷机构的作用下,标签带被平稳送出。当标签运行至剥离板位置时,剥离板独特的角度设计使标签底纸与标签产生分离趋势。此时,真空吸附系统发挥作用,通过吸附平台或吸附头产生的负压,精准吸附住分离出的标签,防止标签在剥离过程中发生偏移或掉落 。

同时,供料器内置的传感器实时监测标签的位置、数量和状态。光电传感器可检测标签是否正确剥离,若出现标签粘连、漏剥等异常情况,系统会立即发出警报并暂停工作,避免不良品产生。

此外,机械传动系统在整个过程中起到关键的驱动作用。步进电机或伺服电机[敏感词]控制标签带的输送速度和距离,确保每一张标签都能准确送达指定位置,与后续的贴标机构无缝对接,完成贴标动作。

特点

高精度剥离

标签剥离剥标供料器采用精密的机械结构和先进的控制系统,能够精准控制标签的剥离角度和位置。结合视觉检测技术,可对标签图案、尺寸进行识别和校准,实现 ±0.5mm 甚至更高精度的标签剥离,满足高端产品对贴标精度的严苛要求。

高效稳定

该供料器的剥离速度可达每分钟数百张,且运行稳定可靠。其自动化的工作流程减少了人工干预,避免了因人为因素导致的贴标效率低下和质量不稳定问题。同时,连续供料功能确保生产线的不间断运行,大幅提升生产效率。

强适应性

标签剥离机剥标供料器可适应不同材质(纸质、塑料、金属箔等)、不同尺寸(小至几毫米,大到几十厘米)的标签剥离。通过简单的参数设置和机械部件调整,就能快速切换不同规格的标签,满足企业多品种、小批量的生产需求。

智能监测与报警

具备完善的智能监测功能,通过多种传感器实时监控设备运行状态和标签剥离情况。一旦出现异常,如标签堵塞、底纸断裂等,系统会立即发出警报并自动停机,同时显示故障信息,方便维修人员快速定位和解决问题,降低设备故障对生产的影响。

标签剥离剥标供料器凭借其科学的工作原理和突出的技术特点,为自动化贴标生产提供了可靠保障。随着技术的不断进步,其性能将进一步提升,在更多领域发挥重要作用,助力企业实现生产的智能化与高效化。

微信咨询

微信咨询