关于我们

标签飞达剥标机供料器,剥离导电胶标签供料实现快速稳定喂料

Time:2025-06-17

Page views: 1430次

针对导电胶标签快速且稳定的剥离与供料需求,以下是经精心筛选的标签飞达剥标机供料器设备解决方案以及选型建议,主流技术特征和应用:

一、适用设备类型与核心技术

-

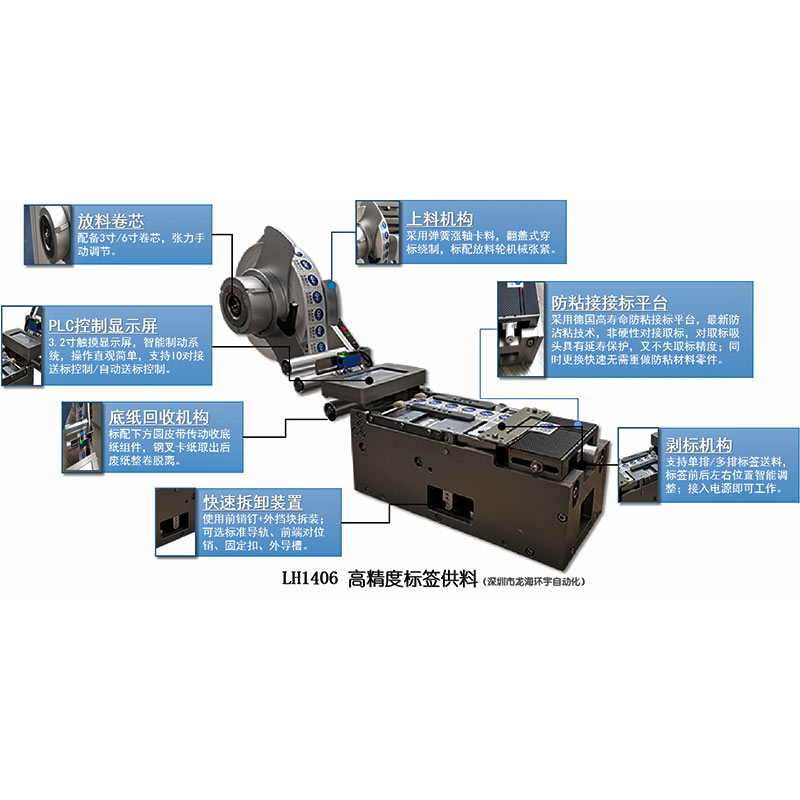

高精度平台式剥标机供料器

- 该供料器专为导电胶、泡棉等特殊材质而设计,其贴装台采用防粘材料,可有效避免胶残留问题。

- 具备±0.1mm的剥离精度,支持与机械手直接对接,无需额外配置视觉系统。

- 代表机型:龙海环宇LH1408系列,适用于双层/三层标签,配备张力控制装置,可确保出标稳定性。

-

可调式后撤/回退飞达

- 优势在于通过反向剥离方式减少标签位移,适用于易翘曲的导电胶材料。

- 支持宽度范围为50 - 120mm(可定制至140mm),能够兼容不同的底纸规格。

- 代表机型:龙海环宇后撤式飞达,集成光纤传感器,可实时监控出标位置。

-

前推式快速换料供料器

- 适用于单层导电胶标签,采用模块化设计,支持在10秒内完成换料操作,有助于提升产线效率。

- 可选择导轨快插结构,以适配自动化产线集成。

二、关键性能参数参考

三、龙海环宇主流技术推荐

特色:提供机械手专用供料器,采用平台式剥离防粘设计,产品出口至30多个[敏感词]。

-

适用场景:适用于卷式导电胶标签的高速剥离,可兼容多列物料布局

- 典型案例:应用于华为/小米供应链的散热片贴标设备。

特色:滚贴式飞达可解决高粘度标签问题,提供免费试样服务。

四、选型注意事项

- 粘性控制:由于导电胶易残留,建议优先选择带有防粘涂层或具备碾压修整气泡功能的机型(如采用专利设计的碾压滚轮结构)。

- 环境适配:若车间温湿度波动较大,需确认设备是否配备恒温料仓。

- 验证需求:要求供应商提供现场试机服务,以测试标签剥离的完整度以及连续供料的稳定性。

实际选型时,请结合物料样本和产线节拍进行评估。更多技术细节可访问:龙海环宇官网

微信咨询

微信咨询