Contact Us

Sales Hotline:13602637212(Same number on WeChat)

Company Office Number:+86-0755-23730499

- Product Details

- Product video

- Application Cases

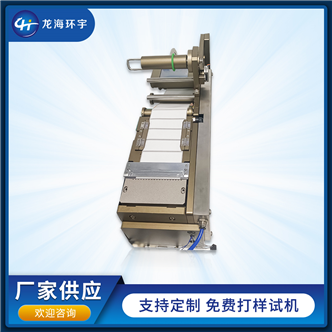

龙海环宇生产的剥标机型拥有品质稳定,适应性强,剥标精准、速度快的特点,同时可根据客户自身需要,承接非标定制;

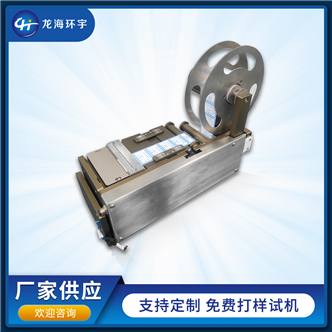

•操作方式:自动剥离,人工手动或机械手取标;

•出标精度:±0.1mm(不含标签,材质误差);

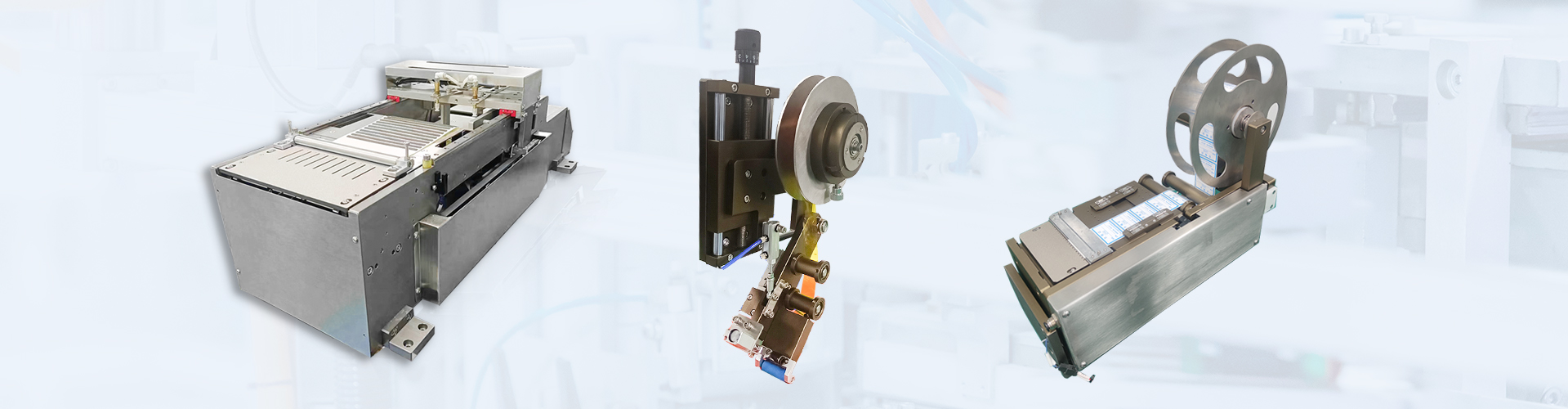

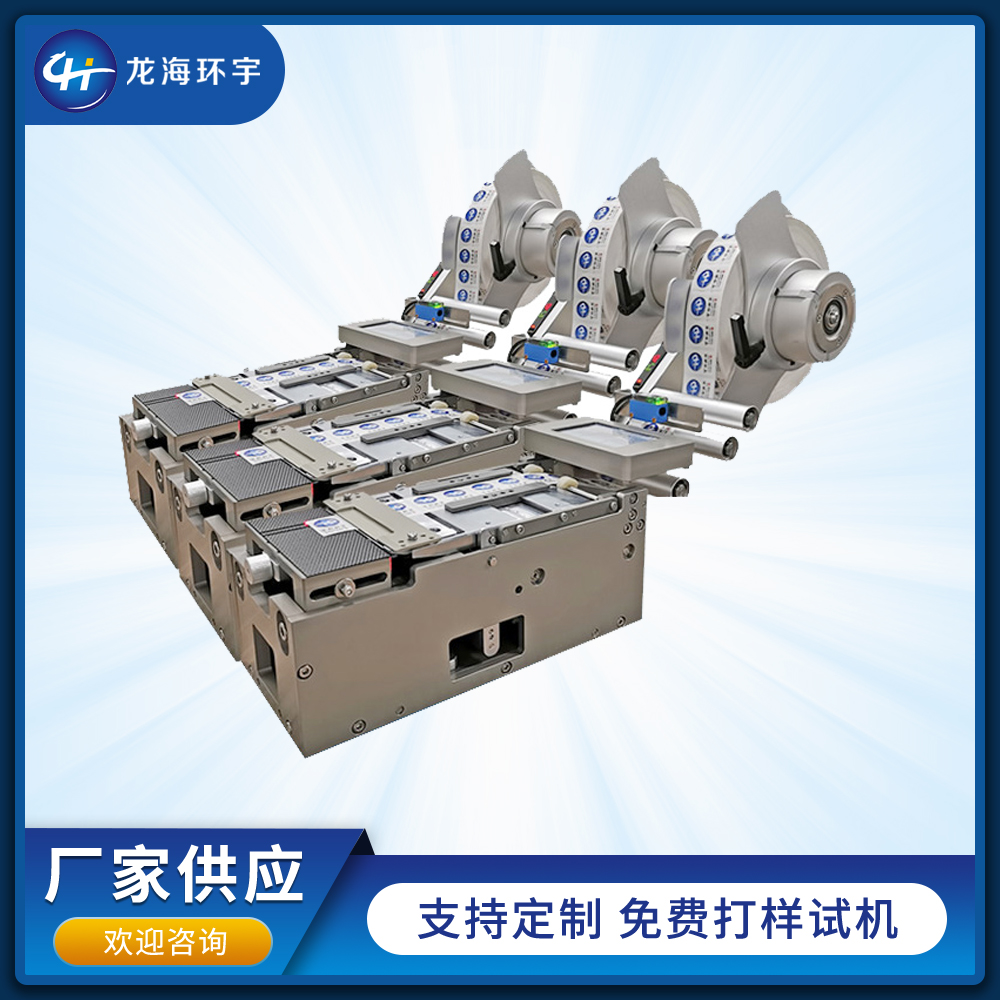

•设备说明:械手高精度标签送料器LH1406(送标feeder),是由龙海环宇自动化公司与华南理工大学教授联合研发,专门配合机械手贴标、贴片料的设备。本设备能专业输送单排/多排标签、手机辅料、FPC 补强/绝缘材料,配合标签贴装设备、手机辅料贴装设备、FPC 补强机等使用。设备稳定、精巧灵活,不但解决了取标时的精度问题(精度可达到±0.1mm),大多数情况下可以不用配视频系统即可达到贴合精度,能为使用方大幅提高生产效率节省成本,是高精度贴标贴料时的配套设备。

产品外观:.jpg)

贴标示例:

技术参数:

| 类目 | 关键参数范围 |

| 外型尺寸: |

1)长度:放料支架立装后总长 500mm:放料支架平装后总长600mm; 2)宽度:总外宽 150mm; 3)高度:剥标机本体110mm(未包含放料支架) |

| 出标精度: |

1)标签低纸横向摆动:X方向<±0.1mm; 2)标签剥出后的前后差异:Y方向≤±0.1mm |

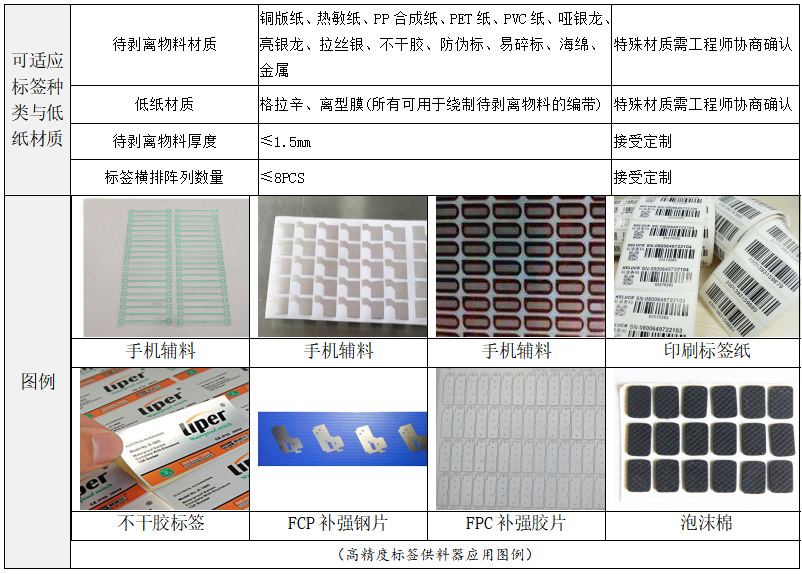

| 送料宽度: | 可过低纸[敏感词]宽度:70/100/120/170mm |

| 送料排数: | ≤8PCS |

| 卷芯: | 3寸/6寸 |

| 产品尺寸: | 产品尺寸≤30*60mm |

| 产品间距: | 产品小间距3mm: |

| 电源: |

1)无需控制接入24V3A电源即可工作; 2)支持10对接送标控制/自动送标控制 |

| 电机[敏感词]速度: | 600转/分 |

| 触屏规格: | 3.2寸触摸屏 |

| 驱动方式: | 雷寒42步进+减速箱 |

| 固定方式: | 可选标准导轨、前端对位销、固定扣、外导槽 |

| 接料平台: | 采用德国高寿命防粘接标平台(非硬性对接取标,对取标吸头具有延寿保护,又不失取标精度:同时更换快速无需重做防粘材料零件) |

结构与细节:

.jpg)

.jpg)

性能特点:

•适应范围广:不同材质的标签均可适应,单排、多排标签均可适应;铜版纸、热敏纸、PP合成纸、PET纸、PVC纸、哑银龙、亮银龙、拉丝银、不干胶、防伪标、易碎标等;

•高精度定位、高速贴装、无卷报警:精度士0.1mm;接入电源即可工作,支持1O 对接送标控制/自动送标控制;带无卷料或料卷用完报警提示功能;

•产品快速装夹:

上料:采用弹簧涨轴卡料,翻盖式穿标绕制(还可接受接受气涨轴或其他挂料方式);

下底纸:钢叉卡纸取出后废纸整卷脱离;

装拆机头:前销钉+外挡块;

•性能稳定操作简便:采用雷赛步进电机驱动送标,送标稳定准确;剥离的标签被取用后,自动剥离下一张标签;可一次性剥离多排标签;

•选材优良、品质过硬:主要部件采用不锈钢,刚性十足不变形、不生锈,美观大方;同时遵照 ISO9001 质量管理体系制作,注重品质与用户使用体验,符合 GMP优良制造标;

•其它行业优势:该设备使用德国[敏感词]防沾粘技术,取标对接非硬性接触对取标精度不影响的前提下保证吸头寿命;当贴标精度要求≥+0.3mm时可不依赖工业相机;接标台更换简单方便成本低无需备做接标台零件,为客户节约硬件成本提升设备稼动率。

Note: The above products and pictures are for reference only. For more details, please feel free to contact our factory by phone! ! !

微信咨询

微信咨询