Contact Us

Sales Hotline:13602637212(Same number on WeChat)

Company Office Number:+86-0755-23730499

- Product Details

- Product video

- Application Cases

*节约成本:物料无需做成卷料,节约标签制作成本,片料上机即可自动剥离;

*适应范围广:不同材质的片料标签均可适应,单排、多排标签均可适应,兼容性强,供料速度快,出料精度高;

*性能稳定:可选配双张物料检测,异常报警输出,料仓自动供料;

*彩色触摸屏可快速设定参数;

*接标平台采用防粘材料,轻松解决胶粘吸不起来的问题。

技术参数:

|

类目 |

关键参数范围 |

|

剥离CT: |

出标速度≤35mm/s,片料单张自动切换时间4~5s; |

|

出标精度 |

Y 方向(出标方向):±0.5mm;X 方向:±1mm |

|

供料器兼容片料标签尺寸: |

标签长>4≤100mm,宽>5≤150mm; 底纸长120mm-365mm,宽度 65mm-150mm, |

|

料仓上料数量: |

料仓可放料高度55mm(不同厚度和重量可放数量不同); |

|

标签厚度: |

0.1mm-0.8mm(其余厚度可来样定制) |

|

片料底纸厚度: |

0.035-0.13mm |

|

物料平整度要求: |

每50mm长度底膜变形度±1.5mm |

|

剥离成功率: |

>98% |

|

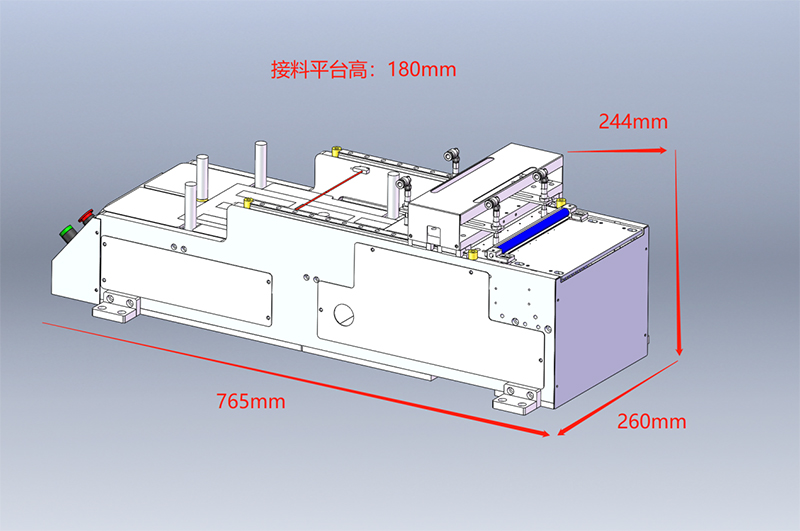

整机尺寸 |

(L)765×(W)260×(H)244mm |

|

标签排版及标签要求 |

|

|

底纸参数范围: |

长度:120mm-360mm,宽度 65mm-150mm, |

|

标签要求: |

长>4mm,宽>5mm,可单列及多列,多列时标签间隔尺寸>2mm; |

|

排版要求: |

标签与底纸排布时前后端预留≥15mm 以上空带,左右预留2mm 以上空带;底带离型力<20g,底带切线深度<1/3 底带厚度 |

|

适用范围 |

|

|

适用物料类型: |

铝箔、铜箔、Mylar、双面胶、标签、导电布、高温胶、锅仔、泡棉。 |

|

整机动作简介 |

|

| 换料方式 |

人工将片状材料放入料仓(机器通过无料报警提示,换料时间根据片料及标签厚度定义) |

|

剥离方式 |

通过咬合式牵引剥离法,将标签剥离到接标平台,平台通过测物传感器定义出标位置 |

|

排废方式 |

剥离完成的底纸通过排废通道排出设备 |

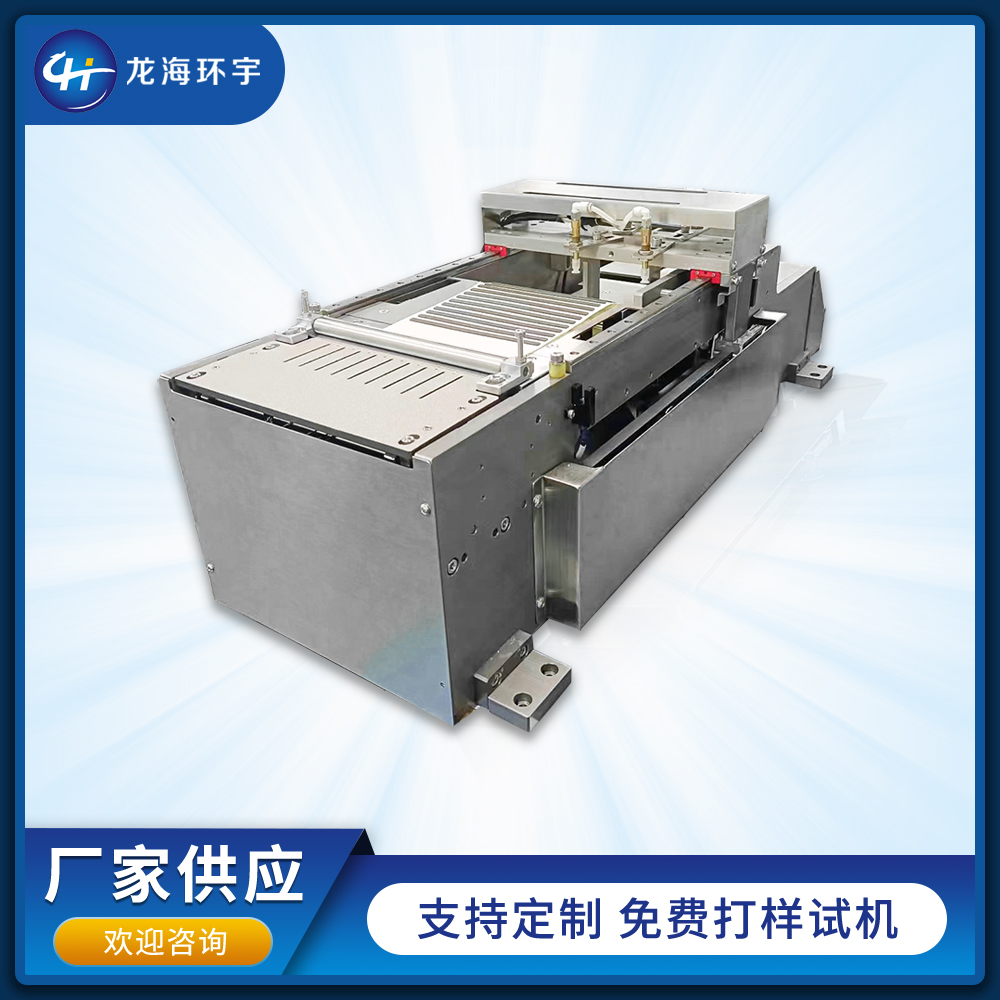

设备图片:

Note: The above products and pictures are for reference only. For more details, please feel free to contact our factory by phone! ! !

微信咨询

微信咨询