视觉贴标机使用指南:常见问题与故障处理大全

视觉贴标机使用指南:常见问题与故障处理大全

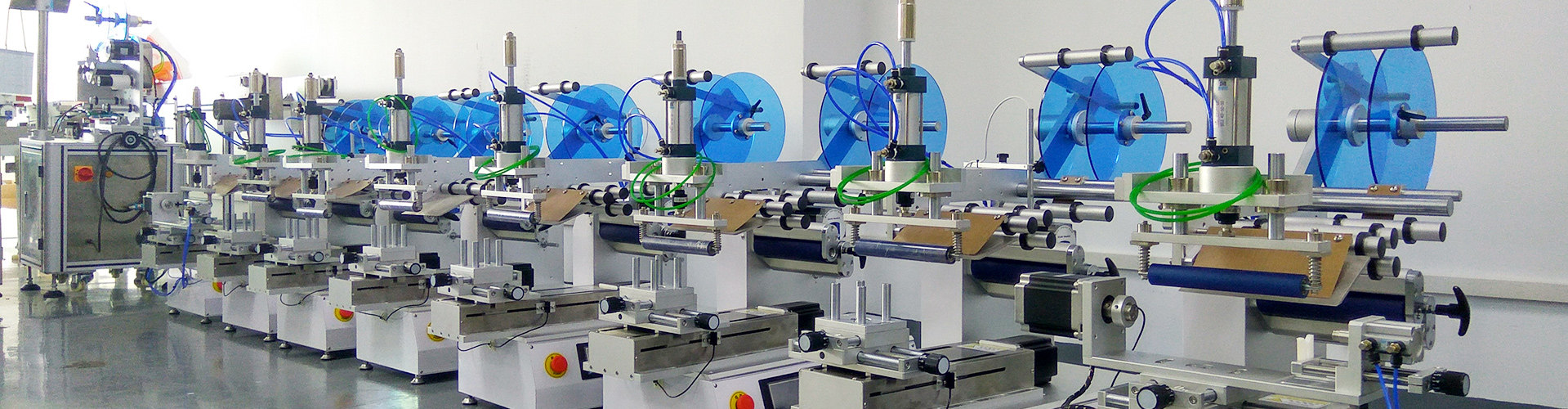

本文介绍了龙海环宇视觉贴标机常见故障问题,以及处理流程方法,为广大客户正常使用提供技术指导。

一、视觉贴标机基础操作要点

视觉贴标机作为智能包装设备的核心装备,稳定运行需要规范开机操作流程:

1. 开机准备步骤:

检查气源压力(0.4-0.6MPa);

确认相机/镜头无污损;

校准传送带速度与视觉触发时序;

验证光源亮度一致性(使用灰度卡测试)。

2. 日常操作保养规范:

每班次清洁镜头防尘玻璃;

定期备份系统参数(建议每周1次);

更换产品型号时需重新标定;

异常报警立即停机排查。

二、常见问题诊断与处理方案

1. 图像采集类故障

(1)图像模糊

可能原因:

A. 镜头焦距未调准(占比42%)

B. 相机快门速度不匹配(占比28%)

C. 产品振动超标(占比18%)

解决方案:

A. 使用靶纸重新对焦

B. 调整快门至1/1000s以上

C. 增加减震装置,检查结构刚性。

(2)图像过曝/欠曝

参数调整指南:

现象 调整参数 推荐值

过曝 光源亮度↓ 降低30%-50%

相机增益↓ 建议<15dB

欠曝 曝光时间↑ 100-500μs

光圈值↓ F2.8→F4

2. 识别定位类故障

(1)匹配失败

处理流程:

检查模板是否被遮挡

验证产品位置偏移量

调整匹配阈值(0.7→0.6)

启用旋转补偿功能

(2)坐标偏移

九点标定法复查步骤:

使用标准标定板

采集9个位置点图像

计算转换矩阵残差(应<0.1pixel)

更新标定参数

3. 机械执行类故障

(1)贴标位置偏差

三维补偿方法:

X/Y向:调整视觉坐标偏移量

Z向:修正吸标高度参数

角度:修改旋转补偿系数

(2)标签剥离异常

排查清单:

剥离板角度(标准30-45°)

出标速度匹配(建议比传送带快5%)

标签底纸张力检测

三、进阶故障处理技巧

1. 复杂场景解决方案

问题类型 技术方案 实施效果

反光表面 使用偏振镜+低角度环形光 反射抑制率>80%

透明包装 配置背光光源+红外相机 识别成功率提升至95%

曲面贴标 3D视觉定位+柔性贴标头 弧度适应范围±15°

2. 系统稳定性提升

抗干扰三要素:

电磁屏蔽:信号线加磁环

振动隔离:安装阻尼器

温度控制:环境温度23±2℃

预防性维护计划:

周期 维护项目 器材

每日 镜头清洁/气路排水 无尘布+无水酒精

每月 导轨润滑/皮带张力检测 锂基脂润滑脂

每季度 光源亮度校准/相机标定 标准灰度板测试

四、[敏感词]智能诊断技术

1. 远程运维系统

实时监控设备状态(电压/温度/振动)

自动生成故障报告(含解决方案推荐)

支持AR远程指导维修

2. 预测性维护

基于大数据的寿命预测:

伺服电机剩余寿命分析

光源衰减预警

易损件更换提醒

3. 自学习系统

自动记录处理成功的异常案例

建立解决方案知识库

相似故障自动匹配历史方案

五、操作员必备技能矩阵

技能等级 能力要求 培训时长

初级 基础操作/简单故障处理 8学时

中级 参数优化/机械调整 24学时

高级 算法修改/系统集成 80学时

专家 二次开发/特殊场景解决方案设计 200学时+

六、实用排查流程图

A[故障现象] --> B{图像类?}

B -->|是| C[检查相机/光源/镜头]

B -->|否| D{机械类?}

D -->|是| E[检查气缸/伺服/传送带]

D -->|否| F[检查电气系统]

C --> G[图像质量达标?]

G -->|否| H[调整光学参数]

G -->|是| I[重新标定]

E --> J[执行机构动作正常?]

J -->|否| K[检查气路/电路]

J -->|是| L[校准运动参数]

七、总结建议

1.建立标准化故障处理SOP(标准作业程序)

2.保留完整的设备维修记录

3.定期进行预防性维护

4.关注厂商龙海环宇的技术更新

掌握本指南列出的解决方案,可解决龙海环宇视觉贴标机90%以上的常见故障。对于复杂系统性问题,建议联系设备

厂商获取专业技术支持。通过规范操作与科学维护,设备综合效率(OEE)可提升至85%以上。

微信咨询

微信咨询