关于我们

贴标机标签走偏如何调整解决

Time:2023-05-17

Page views: 3183次

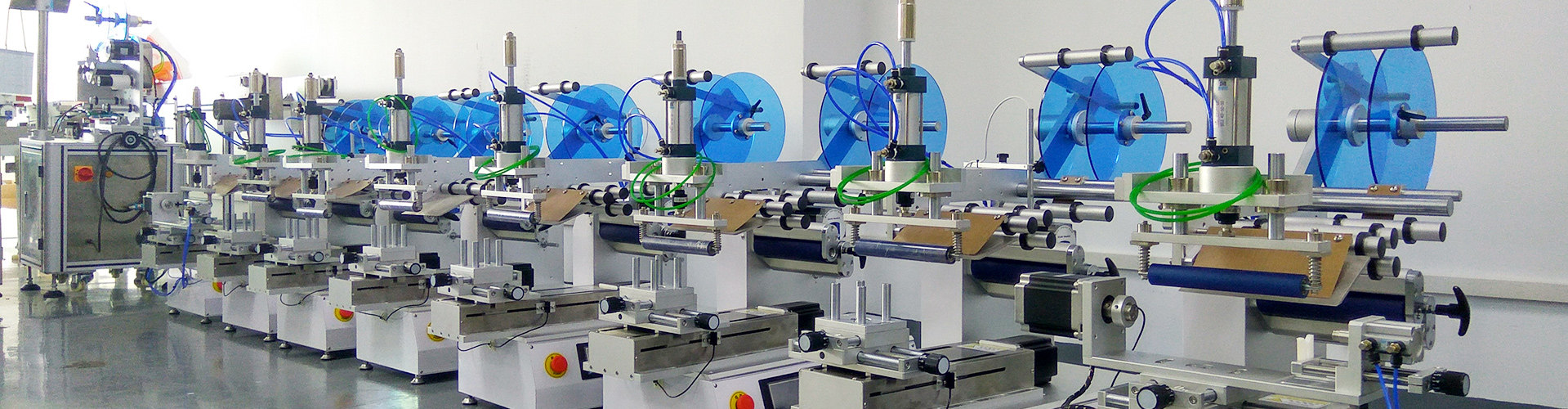

不干胶贴标机操作简单实用,为广大用户带来了贴标的便利。自动贴标机在使用的时候,发生标签走偏的现象,应该怎么解决呢?

标签走偏有很多因素,要具体分析。标签走偏与标签安装、出标不稳、产品轴线不平行、覆标时压力不均、产品误差几个因素有关,要检查是什么原因造成,才能针对性解决。龙海环宇建议用户在使用时要注意几点:

1.标签安装如果有晃动,要检查是否装到卡位,锁紧力度要适中。

2.检查出标是否顺畅稳定:放松牵引,来回拉拉标签,测试是否出标顺利,让其自行导正。标签走正后,固定两侧限位圈,导正标签。

3.检查牵引是否稳定,如有松动,会导致拉力不均匀。

4.检查出标轴线是否平行产品面,如有偏斜,调节贴标头的倾斜度实现平行。

5.检查覆标是否均匀,如有不均,调节底部包胶轴平行度,调节平行即可。

6.检查产品误差,瓶子质量不好也会引起覆标走偏。

以上为解决标签走偏的基本措施,如果还有问题,可以联系贴标机厂家龙海环宇工程师咨询解决。

下一篇:

如何延长贴标机的使用寿命

微信咨询

微信咨询