Contact Us

Sales Hotline:13602637212(Same number on WeChat)

Company Office Number:+86-0755-23730499

- Product Details

- Product video

- Application Cases

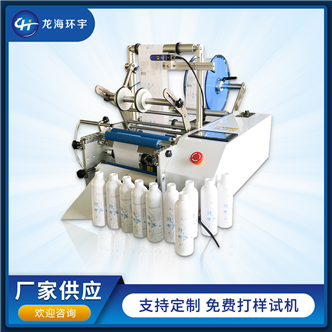

•贴标方式:滚贴;适用于不干胶标签、不干胶膜、电子监管码、条形码、二维码标签、透明标签等;

•贴标精度:±1mm(不含产品、标签、材质误差);

•贴标速度:20~50/分钟(与客户的产品尺寸和人员操作熟练度有关);

•适应标签:适用不干胶标签、不干胶膜、电子监管码、条形码、二维码标签、透明标签等;

•操作方式:具备手动/自动两种控制操作方式;

•设备优点:贴标效果好,精度高,贴膜无气泡无折皱。

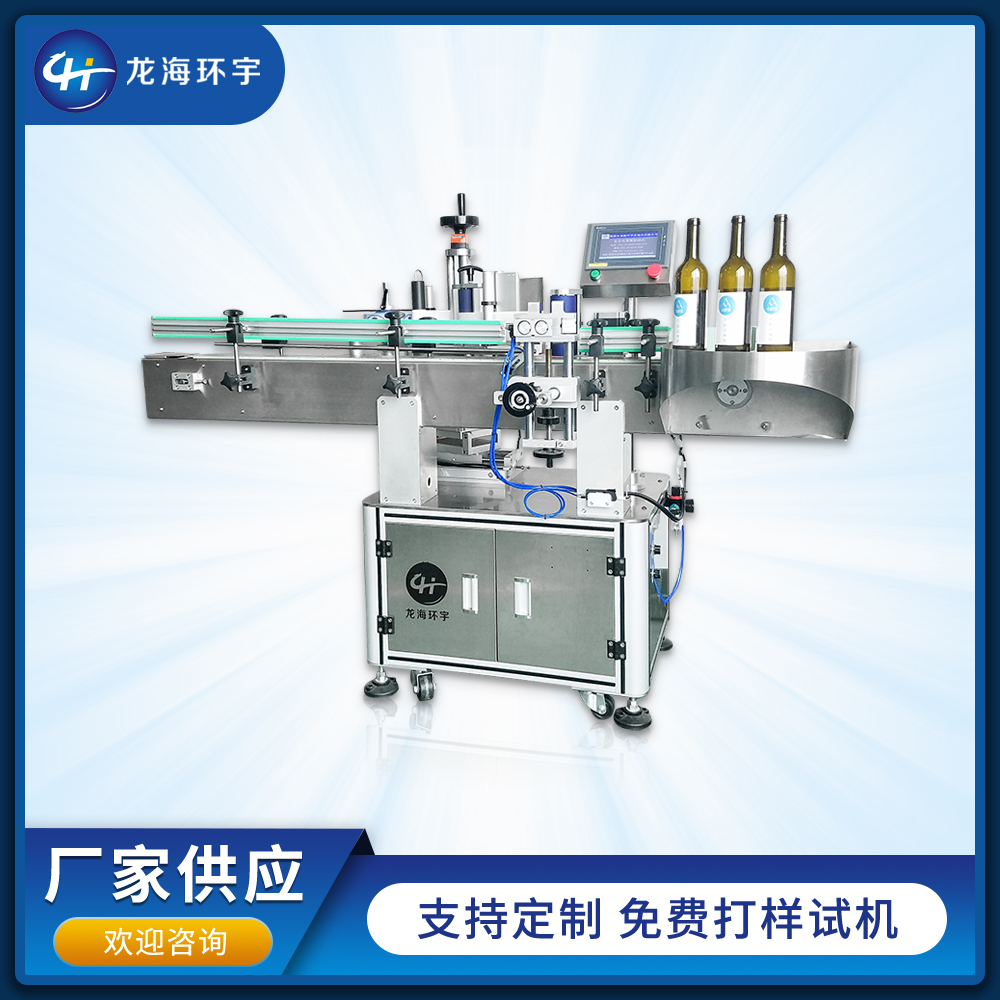

产品外观:

(设备型号:LH1204)

贴标示例:

技术参数:

|

类目

|

关键技术参数范围

|

|

贴标精度:

|

±1mm(不含产品、标签、材质误差) |

|

贴标速度:

|

20~50/分钟(与产品尺寸和人员操作熟练度有关) |

|

适用产品规格:

|

直径:Φ 15mm ~Φ 100mm,高度:10mm~180mm; |

|

适用标签规格:

|

(L)15mm~320mm;(W)10mm~180mm;(根据出标方向) |

|

适用标卷规格:

|

外径:Φ≤280mm;内径:Φ76mm |

|

整体参考尺寸:

|

(L)1920×(W) 1070×(H) 1380 mm |

|

电源及总功率:

|

电压:220VAC、频率:50Hz、功率:750w |

|

重量(kg)

|

约185kg |

|

气压:

|

0.4-0.7Mpa |

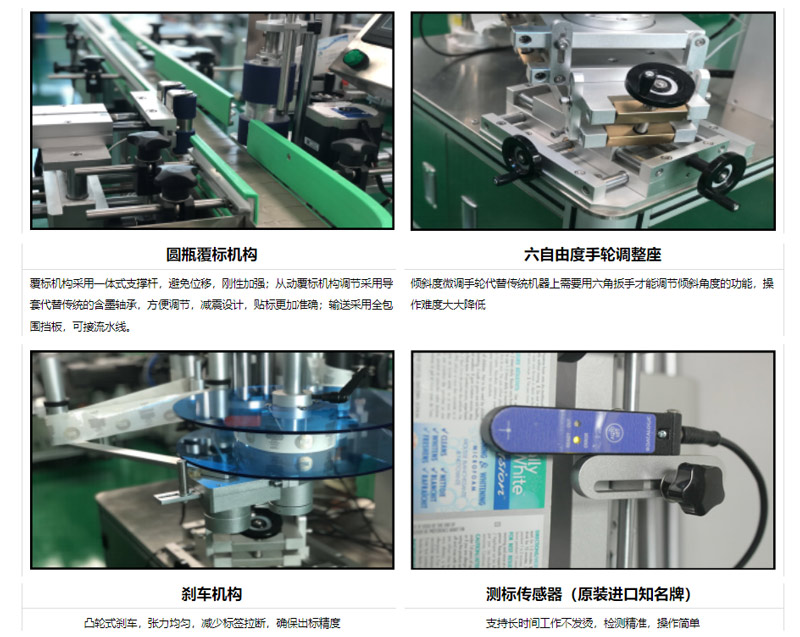

结构与细节:

(LH1204 设备细节图)

性能特点:

1、适应产品多:本机型主要针对各类圆瓶、圆罐等圆柱形或锥形产品的瓶身贴单标、双标,兼容多种直径的产品用同一台机器贴标,选配定位检测装置可实现圆周定位贴标;可根据要贴标产品大小、特点进行适当的大小兼容改造或可非标定制;

2、适用范围广:金属、玻璃、塑胶、PET等不同材质的物体均可适应;不干胶标签、不干胶膜、电子监管码、条形码、二维码标签等均可适应;

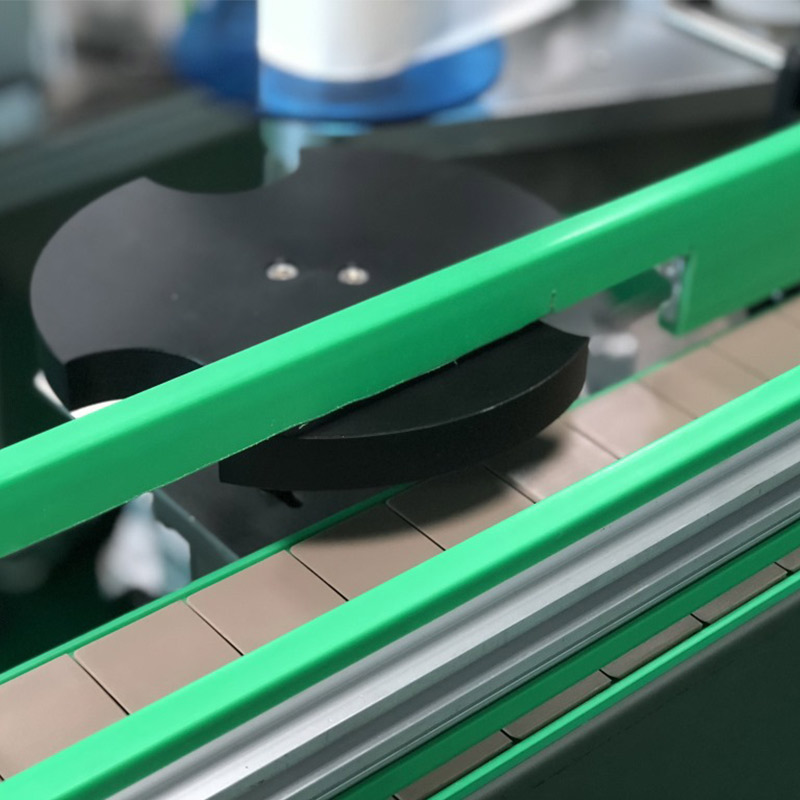

3、贴标精准,稳定性高:贴标效果好,精度±1mm;采用PLC+细分步进电机驱动送标,送标准确;采用凸轮式刹车机构,张力均匀,保证标带绷紧,减少标签拉断,确保标签检测[敏感词];标带绕行纠偏机构,防止标签左右偏移,保证出标精度;

4、功能强大,多功能配置:瓶子站立式贴标,具备自动分瓶功能;标头可自由调节,操作简单;自动光电追踪,具备无物不贴标、无标自动校正和标签自动检测功能,防止漏贴浪费;贴标部位 x/y/z 三个方向以及倾斜度共六个自由度可调,全方位调整无死角,设计成倾斜度微调手轮,操作更简便;可根据客户实际生产状况选择辅助功能配置,既可单机一人操作,也可对接生产线连线运行;

5、智能控制,操作简单:采用人性化设计,PLC编程控制,彩色大触摸屏操作,全中文操作界面,方便直观,强大数据记忆功能,可储存50组贴标参数,操作简单快捷;完善的故障提示和帮助功能;

6、测标、测物电眼采用进口一线品牌传感器:检测灵敏度高,性能稳定,经久耐用;

7、生产管理方便:具备贴标计数、省电模式、光电追踪标签等功能,生产管理更轻松;

8、选材优良、品质过硬:本机型主要部件均采用不锈钢和高级铝合金板,刚性十足不变形、不生锈,美观大方;同时遵照ISO9001质量管理体系制作,注重品质与用户使用体验,符合GMP优良制造标准;

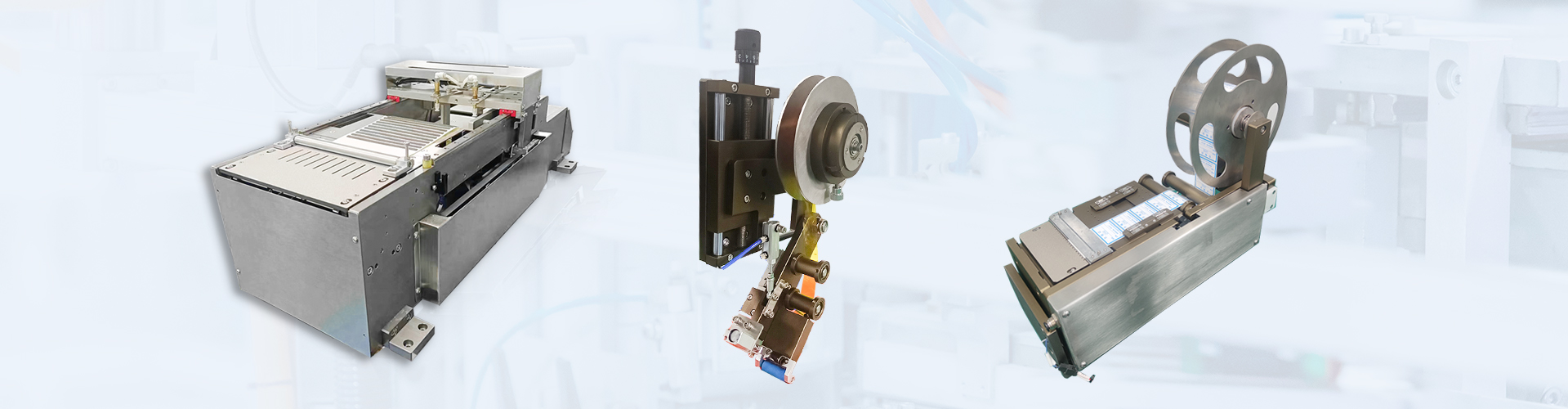

9、可选配功能和部件:

打码器:热打码机能打印生产日期、产品有效期、生产批号等提高生产效率;

[敏感词]传感器 :普通传感器无法检测透明标签,须选特殊透明标检测电眼配套使用;

喷码器 :可配套市场上主流喷码机,在标签指定的位置进行喷码;

读码器 :贴标时读取二维码、条形码等信息,便于建立产品数据库用于产品溯源。

客户使用案例:

Note: The above products and pictures are for reference only. For more details, please feel free to contact our factory by phone! ! !

微信咨询

微信咨询