关于我们

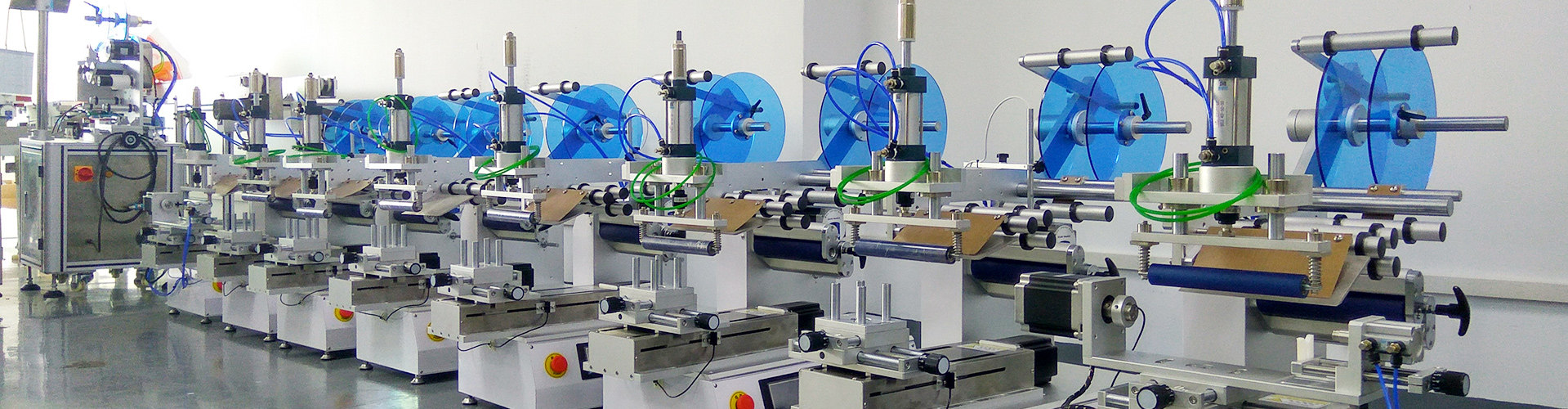

贴标机出厂检验报告

Time:2023-05-16

Page views: 3502次

1、目的

设备测试的目的是为了验证设备质量和配置是否合格。

2、适用范围

贴标机设备

3、测试总则

A. 设备启动

启动:对单个设备多次开关电源,观察每次均能否正常启动。

B. 设备状态

配合产品说明书,检查设备指示灯是否正常。指示灯状态。

C. 端口检查及功能测试

用被测产品(有管理软件则包含软件)检查设备的端口,看通过端口是否能够连接上并且操作设备进行测试。

D. 物理检查

对设备进行物理检查,检查设备出厂机型、编号、客户信息、附件、资料、软件等内容,与合同和产品说明一致为正常。

E. 整体功能检查

对设备进行整体功能检查,检查设备贴标情况,贴标的产能,机器有没异响,确保调试好后螺丝都锁紧。符合合同要求为正常。

F. 外观检查

对设备进行外观检查,检查设备外观应整洁,尺寸、形状符号设计或合同要求,无明显色差,无明显锈蚀,标识清楚、正确。

上一篇:

半自动圆瓶贴标机标签走向图

下一篇:

不干胶贴标机三种贴标方法的优缺点分析

微信咨询

微信咨询