关于我们

不干胶贴标机三种贴标方法的优缺点分析

Time:2023-05-16

Page views: 3183次

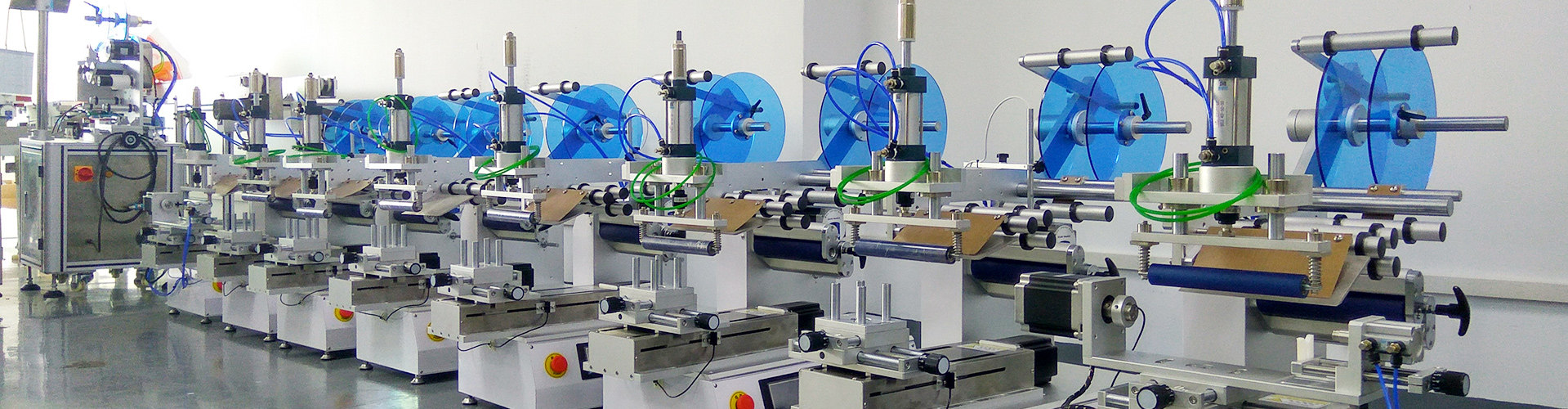

贴标机在企业生产中的作用越来越多人认知,市场上的贴标机虽种类繁多,但万变不离其宗。多年来,贴标机厂家龙海环宇致力于贴标机的研发与生产,总结出贴标机的三种贴标方法的优缺点,不干胶贴标机的贴标方法主要有擦贴法,吹贴法与吸贴法三种。

1,擦贴法的工作原理:当贴标机标签的前缘部分粘贴到产品上后,产品马上带走标签。这种方法的优点是贴标速度快,而贴标精度取决于产品通过贴标机的速度与标签分离的速度,如果两者速度一致,那么贴标精度高,否则,贴标机精度将受到影响。

2,吸贴法的工作原理:当贴标机标签纸离开传送带被吸到真空垫上,真空垫连接到一个机械装置的末端。当这个机械装置伸展到标签与产品接触后,就收缩回去,此时标签贴附到产品上。这种方法的优点是精度高,而且适用于高难度包装产品的贴标工艺;缺点则是贴标速度慢,而且贴标质量不好。

3,吹贴法的工作原理:在吸贴法基础上有所改进,区别在于真空垫的表面保持不动,标签固定和定位在一个“真空栅”上,“真空栅”是一个平面,上面布满几百个小孔。小孔用来维持形成“空气射流”。由这些“空气射流”吹出一股压缩空气,压力很强,使真空栅上的标签移动,让它贴附到产品上。这种方法的优点是精度较高而且具备可靠性;缺点则是过程复杂。

对比以上三种贴标方法发现,擦贴法能够使不干胶贴标机的工作速度得到很大的提高,符合追求高效率的发展趋势。龙海环宇一直致力于贴标解决方案,结合智能控制新技术,生产出精度高、速度快的全自动贴标机。

微信咨询

微信咨询