关于我们

如何延长贴标机的使用寿命

Time:2023-05-17

Page views: 3124次

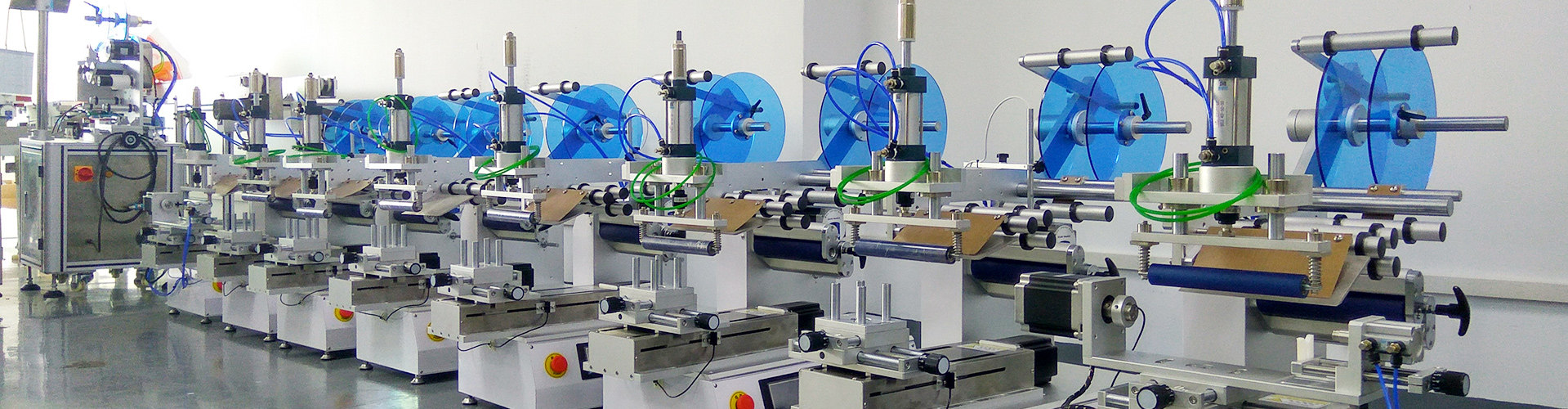

关于自动贴标机寿命问题是很多客户关注的问题,因为机械一旦出现故障就会影响到企业生产效率。那么怎么才能避免这一问题的发生呢,这样就需要我们平时多点注意,规范操作不干胶贴标机和及时保养,这样就会使让机械正常长久运转下去,而不会影响到机械的生产效率。龙海环宇自动化设备有限公司为不干胶贴标机使用者们分享专业的贴标机保养的一些小妙招,使贴标机得以更好的发挥效能,并延长使用寿命。

首先,贴标机保养一定要做好清洁工作。贴标机在运行过程中很容易吸进去灰尘,因此一定要定期清理贴标机上的灰尘。贴标机暂时闲置不用时,应该拔掉电源,并用遮尘布盖上,避免灰尘落在贴标机上面。另外,贴标机的高温带也要定期除污,这样才能更好的保证贴标机高质量的运作。

其次,贴标机养护一定不要忘了涂点润滑油。贴标机在工作2、3个月后应在转动的部件位置涂抹一点润滑油,可以保证贴标机各个部件顺滑。贴标机在运作了一定时间后应该进行定期保养,一方面保证了贴标机运作效果良好,同时还可以延长全自动贴标机寿命。

上一篇:

贴标机标签走偏如何调整解决

下一篇:

贴标设备不出标的原因及解决办法

微信咨询

微信咨询